With dosing pumps (oscillating positive displacement pumps), a defined liquid volume is sucked in in the return stroke and fed into the dosing line at the discharge stroke. The dosing capacity can be changed by setting the stroke volume and the dosing strokes per time unit. In this way, a consistently accurate dosing is achieved even with varying counter pressure.

Doseuro makes four types of dosing pumps;

1. Spring return plunger dosing pumps 2. Spring return mechanical plunger diaphragm pumps

3. Spring return hydraulic plunger diaphragm pumps

4. Spring return hydraulic sandwich plunger diaphragm pumps

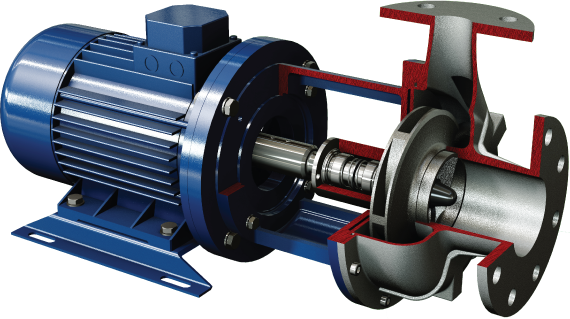

1. Spring return plunger dosing pumps are suitable for use when:

- The dosed liquid is a non-abrasive solution

- A watertight system is not essential (slight leakage over the plunger)

- High pressure is required

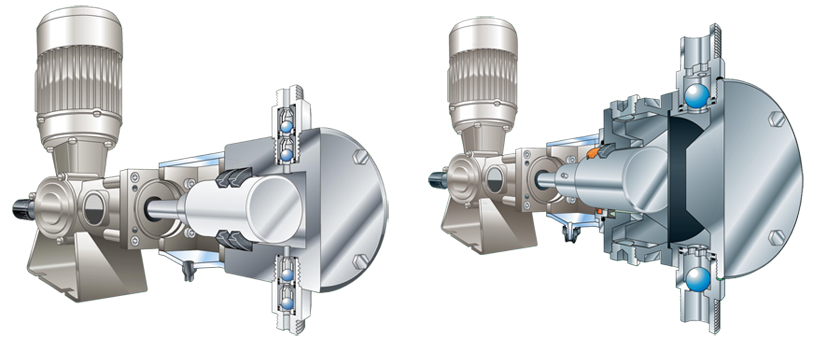

2. Spring return mechanical plunger diaphragm pumps are the best economical and technical solution when:

- The pumped liquid contains small amounts of suspended particles

- The pumped liquid is poisonous

- No leakage is accepted

- No high pressure is required

3. Spring return hydraulic plunger diaphragm pumps are suitable when;

- The dosed liquid contains a small amount of abrasive solids in suspension

- The dosed liquid is a poisonous solution

- No leakage is accepted

- High pressures are required

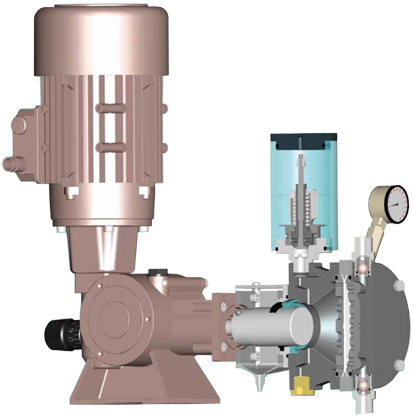

4. Spring return hydraulic sandwich plunger diaphragm pumps are used when;

- The dosed liquid contains a small amount of abrasive solids in suspension

- The dosed liquid is a poisonous solution

- No leakage is accepted

- High pressures are required

- When a safety valve is required for extra safety

- When reliable breakage protection is required for extra safety

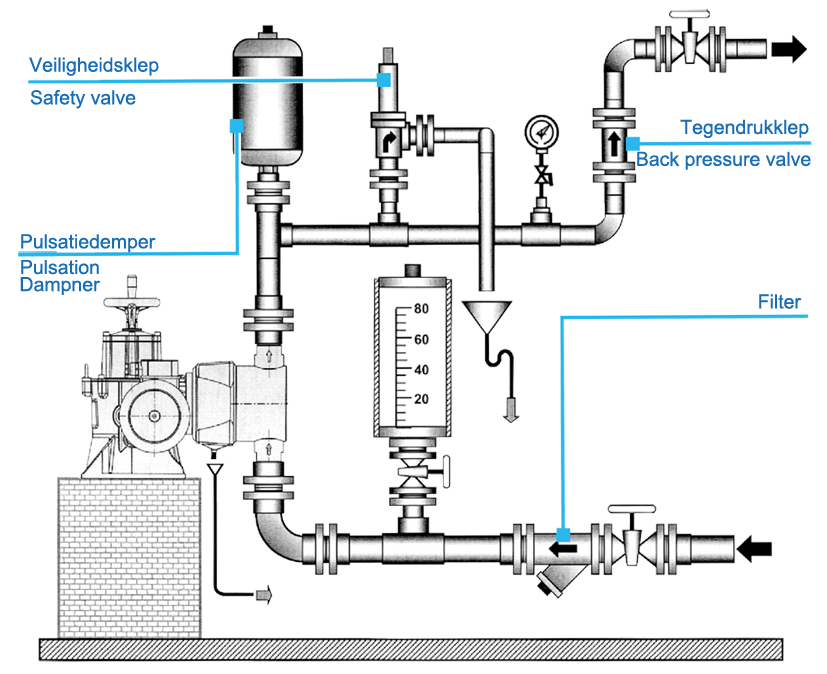

Installation example: