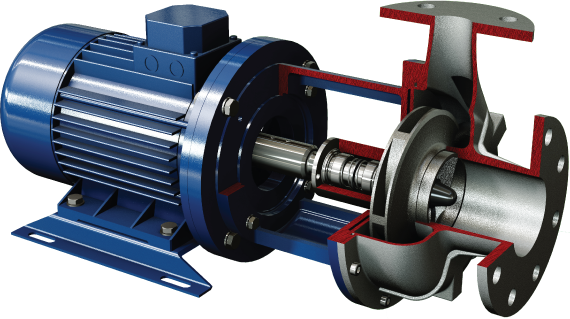

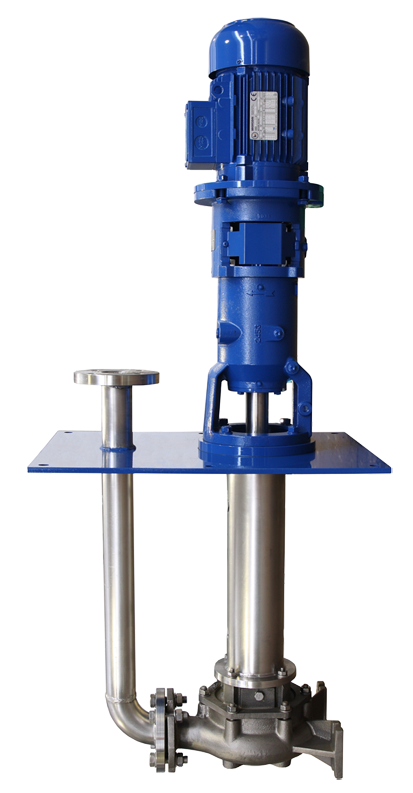

The shaft seal, magnetic coupling or (sliding) bearing in a pump are vital for the operational reliability of the pump. There are many applications where the shaft seal, magnetic coupling or bearing are a problem with regard to operational reliability. For example, because the medium crystallizes, there is a lot of foam or air in the liquid, the medium is very hot, or because level control is difficult. The solution is a pump without a shaft seal or bearing in the medium; the cantilever pump.

Click here for an animation of the working principle of our cantilever pump.

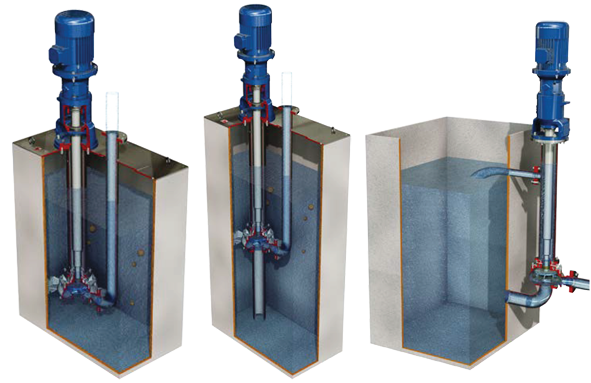

Our cantilever pump is available in the following versions and is also available Atex certified.