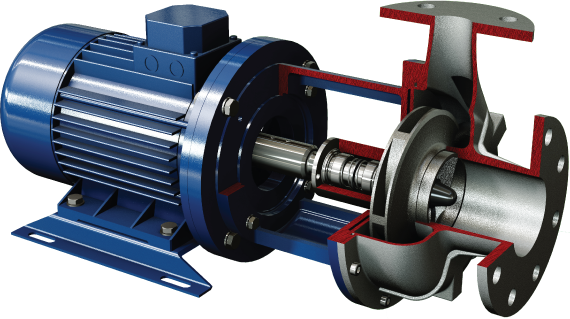

"Centrifugal pumps move liquid by means of centrifugal forces. The liquid must not be too viscous for optimal centrifugal pump functioning. It's design is generally more simple than that of a positive displacement pump, which results in lower cost."

A number of centrifugal pumps are made according a specific norm or standard. Even for these pumps there is a lot of difference among brands. The comparison stops with somewhat similar pump specifications. Other selection criteria are underestimated in importance and sometimes forgotten. These selection criterea however make the difference between a good and bad pump selection. IB-Pompen makes the difference.

Working principle and liquid flow in a centrifugal pump:

Centrifugal pumps can be devided into three groups:

Centrifugal pumps with overhanging impeller(s) (bearings one side), available in submerged and dry installation, horizontal of vertical execution, bearing(s) in the drive unit (close coupled) or with bearing housing (long coupled on base). Belonging to this group : (heating)-circulating pumps, magnetic drive pumps, canned pumps, end suction pumps acc. DIN24255, end suction pumps acc. DIN24256, immersible- & cantilever pumps, barrel pumps, submersible pumps, vertical immersible with lower bearing, mixed-flow- and propellor pumps.

Centrifugal pumps with "impellers between bearings". This is the smallest group, which includes split-case pumps, bore hole- and deepwell pumps.

Special execution centrifugal pumps ; selfpriming centrifugal pumps, recessed impeller (vortex) centrifugal pumps and filter pumps.

We are glad to help you with the right pump selection!